Packaging Tools

- Semi-Automatic Wire Bonder

- Wafer Dicing Tool

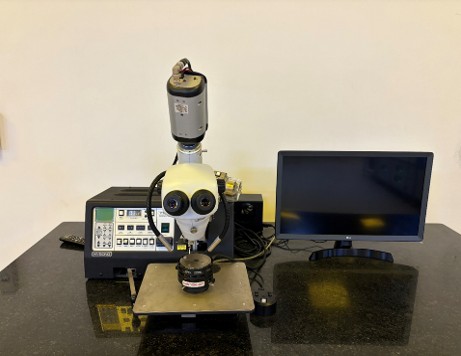

Semi-Automatic Wire Bonder

NAME OF INSTRUMENT: SEMI-AUTOMATIC WIRE BONDER

COMPANY: HYBOND (USA)

MODEL: HYBOND 626

APPLICATIONS: Wire bonding of sensors, and semiconductor devices on a chip for electrical connections. It enables precise placement and bonding of wires, ensuring low resistance, high reliability, and consistent performance.

Specifications

| Parameter | Specification |

|---|---|

| Ultrasonic (U/S) System | PLL self-tuning 62.5 KHz (nominal), ±2.5 KHz |

| U/S Power Range | 0–0.2 W (low), 0–2 W (high) |

| Bond Time Range | 0 ms to 900 ms |

| Bond Force Range | 12 g to 250 g |

| Temperature Control Range | Ambient to 250 °C |

| Bondable Wire Diameters | Ball: 0.7–3.0 mil (18–76 µm); Wedge/Peg: 0.5–3.0 mil (12.7–76 µm) |

| Bondable Ribbon Dimensions | Up to 1 × 20 mil (25.4 × 510 µm) in Wedge or Peg mode |

| Bondable Wire/Ribbon Materials |

Ball: Gold, Platinum Wedge: Gold, Aluminum, Copper, Silver, Platinum |

| Bond Head Movement/Reach | Motorized (servo); switch- or foot-controlled; horizontal reach: 6.5 in (165 mm) |

| Bond Actuation/Bond Height Detect | Sensor at bond surface contact |

| Z Travel / Vertical Bonding Window | 0.750 in (19.0 mm) / 0.740 in (18.7 mm) |

| Table Motion | 4:1 manual manipulator (standard) |

| Input Power Requirements | 90–260 VAC, 50/60 Hz, 10 A max |

| Minimum Bench Space Required | Width: 25 in, Depth: 30 in (63.5 × 76.2 cm) |

| Unit Weight / Shipping Weight | 70 lbs (31.8 kg) / 150 lbs (68.2 kg) |

| Vacuum Requirement | 20 inHg minimum (only needed if using vacuum work stage) |

| Industry Standards | CE |

Wafer Dicing Tool

NAME OF INSTRUMENT: DAD 323 WAFER DICING TOOL

COMPANY: DISCO CORPORATION (JAPAN)

APPLICATIONS: Fully automated precisions saws cut the wafer. The device can be used for processing substrates such as silicon, glass, ceramic, SiC and other structures up to 6 inches in size.

Specifications

| Specification | Unit | Value |

|---|---|---|

| Max. workpiece size | – | Φ6 inch / 150 mm × 150 mm (user-specified specification) |

| X-axis Cutting range | mm | 160 |

| X-axis Cutting speed | mm/s | 0.1 – 800 |

| Y-axis Cutting range | mm | 162 |

| Y-axis Index step | mm | 0.0001 |

| Y-axis Index positioning accuracy | mm | 0.005/160 (Single error), 0.003/5 |

| Z-axis Max. stroke | mm | 32.2 (Φ2 inch blades) |

| Z-axis Moving resolution | mm | 0.00005 |

| Z-axis Repeatability accuracy | mm | 0.001 |

| θ-axis Max. rotating angle | deg | 320 |

| Spindle Output | kW | 2.0 at 40,000 min⁻¹ |

| Spindle Rated torque | N·m | 0.48 |

| Spindle Revolution speed range | min⁻¹ | 3,000 – 40,000 |

| Machine dimensions (W × D × H) | mm | 490 × 870 × 1,600 |

| Machine weight | kg | Approx. 400 |