home 2

The Office Of Corporate Relations

The Office of Corporate Relations at IIT Jodhpur is dedicated to strengthen the Institute’s corporate relations and enhance Industry engagement through joint R&D programs in collaboration with industries, exploring industry-linked endowments, CSR project opportunities, fellowships and scholarships and building a long lasting Industry- academia relationship based on mutual objective and shared goals, aligning with IIT Jodhpur’s future aspirations.

Collaborative R&D

Developing research programs with industry partners

Fellowships & Scholarships

Enabling industry-linked academic support

CSR Initiatives

Working with corporate foundations for social impact

Causes to Donate

CSR - Corporate Social Responsibility

Contributions to IIT Jodhpur by corporations qualify under the mandatory CSR obligation of companies as per Section 135 of the Companies Act.

Corporate Support Framework

Approved under Schedule VII of Section 135 of the Companies Act, making corporate contributions to IIT Jodhpur eligible under mandatory CSR obligations.

Registration Details

IIT Jodhpur is officially registered for CSR activities.

CSR Registration Number: CSR00006699

80G Tax Benefit

Companies donating to IIT Jodhpur receive complete tax benefits under Section 80G of the Income Tax Act.

IIT Jodhpur invites corporations to partner in our commitment to developing innovative technologies and sustainable solutions for society's most pressing challenges.

- Wheel Rut Tracker

- Ground Penetration Radar (350 MHz)

- Universal 8 Channel Data Acquisition System (DAQ)

- Thyristor Based Furnace

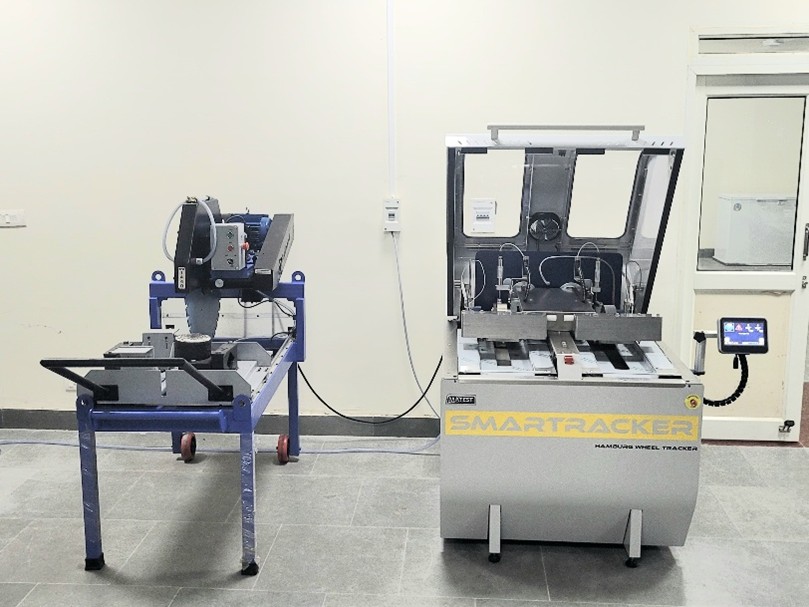

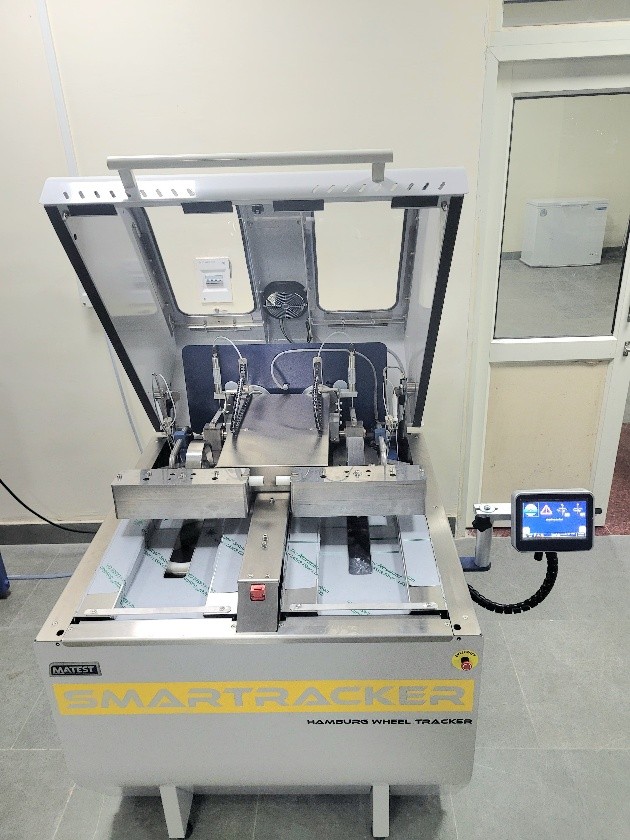

Wheel Rut Tracker

The Matest SmarTracker™ Multi-Wheel Hamburg Wheel Tracker is a high-performance testing system used to assess the rutting and moisture susceptibility of asphalt mixtures under controlled conditions. Compliant with EN 12697-22 and AASHTO T324 standards, it features dual independent wheels for simultaneous wet and dry testing, precise temperature regulation, and automated data acquisition. Its advanced design ensures accurate measurement of rut depth, creep slope, and stripping inflection points, making it an essential tool for evaluating long-term pavement performance in laboratory settings.

Ground Penetration Radar (350 MHz)

Ground Penetrating Radar (GPR) is a non-destructive geophysical method widely used in engineering for the detection and mapping of underground features. One key application is utility locating, where GPR accurately determines the position and depth of underground metallic and non-metallic utilities such as pipes, cables, and ducts. This prevents accidental damage during excavation and supports effective planning in urban development. GPR is extensively employed in civil engineering projects including highways, bridges, tunnels, and railway tracks, for assessing subsurface conditions, identifying voids, delaminations, and structural weaknesses. In geological and archaeological surveys, GPR helps in identifying natural layers, cavities, and buried artifacts without disturbing the ground. Advanced systems like the UtilityScan Pro by GSSI, integrated with the SIR 4000 control unit and a 350 MHz antenna, can investigate depths of up to 12 meters, making it ideal for both shallow and deep subsurface applications. Additionally, the Radan 7 analysis software enhances data interpretation through advanced visualization and filtering capabilities, enabling precise mapping of subsurface structures.

Universal 8 Channel Data Acquisition System (DAQ)

The HBM QuantumX MX840B is an advanced 8-channel universal data logger that allows the connection of sensors and transducers based on 17 different technologies across all its channels. With the support of HBM’s innovative “Plug & Measure” technology, the module automatically recognizes connected transducers, streamlining setup and ensuring accurate measurements. Each of the eight channels can accommodate a wide range of sensor types, including strain gauges in half or full bridge configurations (DC or CF with 4.8 kHz), voltage inputs (100 mV, 10 V, and 60 V), current- fed piezos (IEPE/ICP), piezoresistive full bridges, thermocouples (types K, N, R, S, T, B, E, J, and C), resistance thermometers (PT100, PT1000), resistance up to 5000 Ohm, potentiometric transducers, inductive half or full bridge sensors including LVDTs, and current inputs (±20 mA). Additionally, up to four channels support rotary encoders, counters, frequency/rpm measurements, and the SSI protocol. The module features a high-resolution 24-bit analog-to-digital converter and offers a sample rate of up to 40 kS/s per channel, complemented by active low-pass filters. Renowned for its precision, the MX840B achieves an accuracy class of up to 0.05%, making it ideal for high-performance measurement applications.

Thyristor Based Furnace

The horizontal muffle furnace is a high- temperature thermal processing unit available in the lab, designed for material heating, sintering, and thermal treatment applications. It features a robust construction with a hinged door for safe and easy access and is mounted on a sturdy mild steel stand with the control panel positioned below for user convenience. The furnace offers a compact working chamber of 250 mm × 250 mm × 300 mm and can operate at temperatures up to 1100°C. It uses durable APM grade Kanthal coils as heating elements and a K-type thermocouple to ensure precise temperature monitoring with ±2°C accuracy. A programmable PID controller (1 program × 9 steps) enables accurate temperature control, while a solid-state thyristor regulates power. The chamber is well insulated with a combination of high-temperature bricks and zirconia-blended alumina ceramic fiber blankets, enhancing thermal efficiency and safety. The system operates on a 3-phase power supply (400–415 V, 20 A) and consumes between 6 to 7.5 kW. Additional features include analog voltage and current meters, high-quality switch gears, and safety mechanisms like a slow-blow fuse and user-settable over-temperature protection.

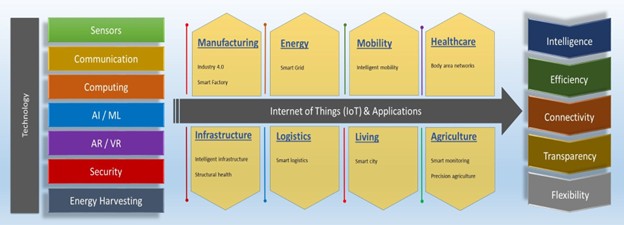

The infographic depicts various aspects of the Internet of Things (IoT) and its applications across multiple domains. On the left side, key technological components are listed, such as Sensors, Communication, Computing, AI/ML, AR/VR, Security, and Energy Harvesting. The center of the image displays specific application areas, categorized into Manufacturing, Energy, Mobility, Healthcare, Infrastructure, Logistics, Living, and Agriculture, with examples like Industry 4.0, Smart Grid, Intelligent Mobility, and Precision Agriculture. On the right, the outcomes or benefits of IoT integration are shown, including Intelligence, Efficiency, Connectivity, Transparency, and Flexibility. This layout illustrates how foundational technologies enable diverse applications which in turn generate various beneficial outcomes.

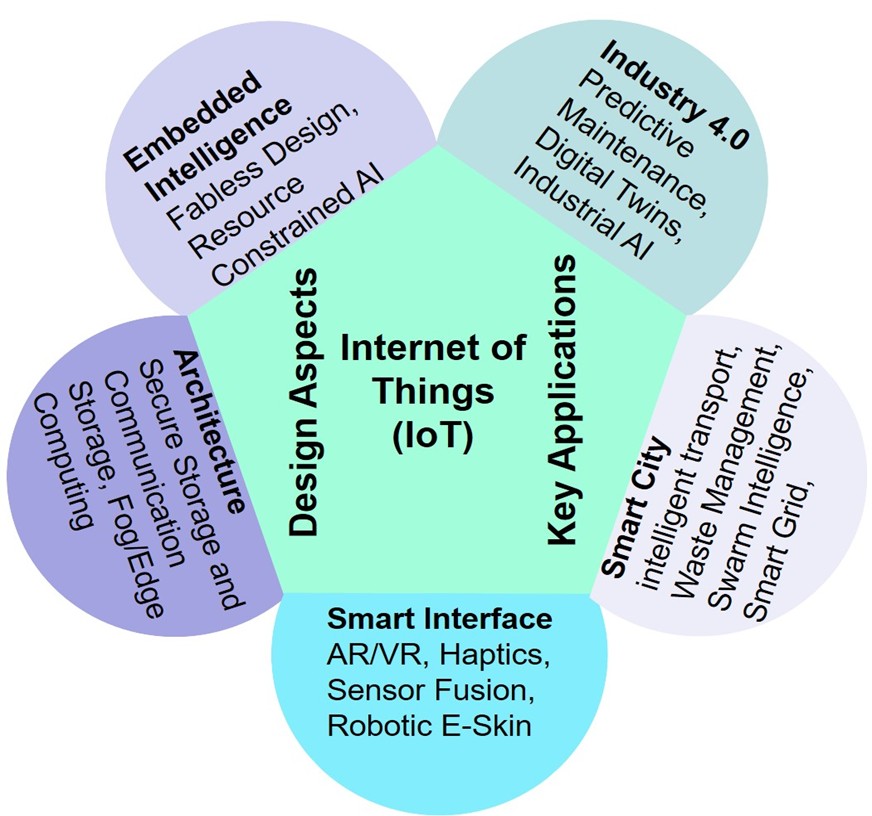

The design aspects of IoT focus on embedded AI and efficient data management within constrained resources, highlighting the importance of secure, scalable architectures and edge computing for real-time processing. The key applications of IoT encompass practical deployments like Industry 4.0, which integrates digital twins and predictive maintenance, and Smart City technologies for optimizing urban infrastructure. Smart Interfaces involve enhancing user interaction through AR/VR, haptic feedback, sensor fusion, and robotic e-skin, making IoT devices more intuitive and effective in real-world applications. Together, these elements define the multifaceted scope of IoT technology.

Online Donation Via QR

Thank you for considering to contribute to IIT Jodhpur. You can contribute to the institute by various modes described below. All contributions to IIT Jodhpur are 100% exempt under section 80G of Income Tax Act. Formal tax exemption receipt for all donations will be issued.

🏛️ Tax Exemption Benefits

💻 Online Donation via QR

Make your contributions using Net Banking or scan the QR Code below.

Online Donation Via QR

Thank you for considering to contribute to IIT Jodhpur. You can contribute to the institute by various modes described below. All contributions to IIT Jodhpur are 100% exempt under section 80G of Income Tax Act. Formal tax exemption receipt for all donations will be issued.

🏛️ Tax Exemption Benefits

💻 Online Donation via QR

📝 Payment through Cheques / DD

🏦 Payment through Net Banking

We accept contributions through Wire Transfers/NEFT/RTGS

Bank Account Details

- ACCOUNT NAME DIRECTOR IIT JODHPUR

- ACCOUNT NUMBER 50100074398977

- BANK NAME HDFC

- IFSC CODE HDFC0000142

- BRANCH ADDRESS 57 B, 9th Chopasani Road, Jodhpur

Email Transaction Receipt

After completing your transfer, email your receipt to:

Include in Email

- Transaction receipt

- Project/purpose details

- Contact information

- PAN number